Mid-Water Ripple

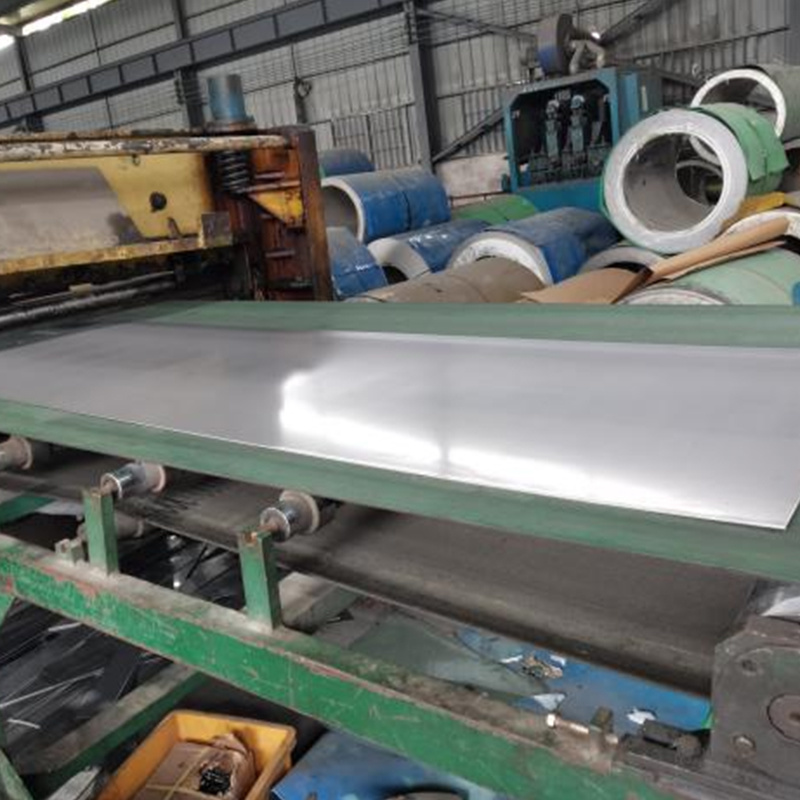

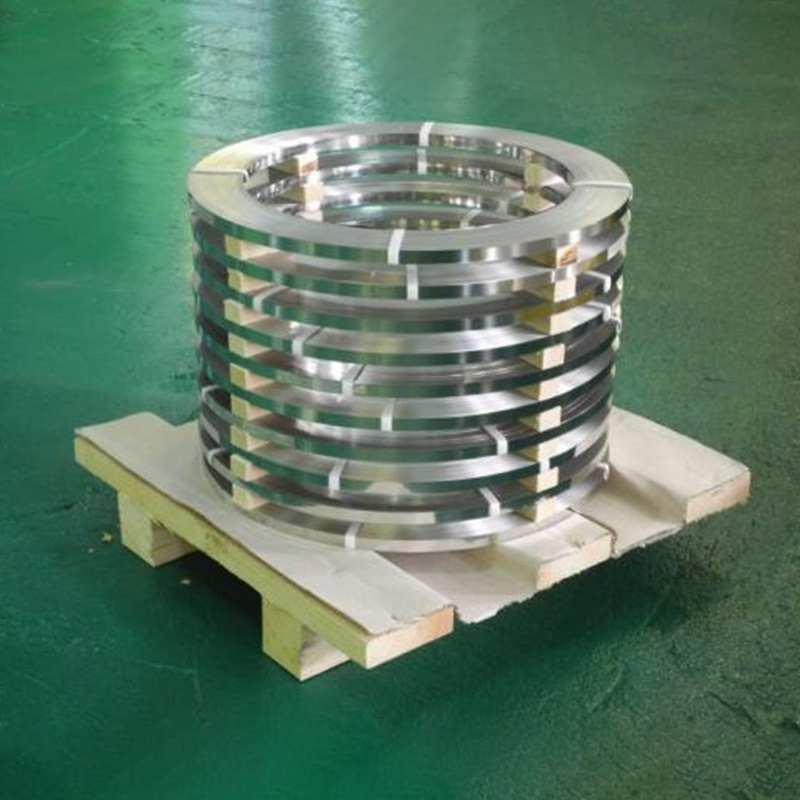

- Commodity name: Mid-Water Ripple

- Product Description

- 200

- 300

- 400

-

To address queries concerning specific environments, please inquire us or select the relevant consultation category. Comparative details for different series are available through the buttons above.

-

Stainless Steel Grades Comparison Table

Grade Core Characteristics Applications 201 Basic high-Mn low-Ni (Mn≈5.5~7.5%), cost ≈70% of 304 Indoor decorative tubes, furniture frames, shelves, lighting fixtures 201J1 Standard 201 composition (Mn≈6.5%, Ni≈1%) General hardware, structural components in dry environments 201J2 High-copper version (Cu≈0.8~1.2%), enhanced deep-drawing performance Shallow-stamped tableware, sinks, simple kitchenware 201J3 High-Ni corrosion-resistant version (Ni≈2~2.5%), corrosion resistance ≈80% of 304 Non-coastal outdoor railings, door/window fittings, elevator decorative panels 201J4 High-Mn strengthened version (Mn≈8~10%), improved hardness/strength Spring plates, low-load fasteners, wear-resistant structural parts 201J5 Nitrogen-strengthened version (N≈0.15~0.25%), optimal overall performance Light-duty 304 substitute applications (appliance housings, bus handrails) Performance Ranking

Property Ranking (Best → Worst) Corrosion Resistance J5 > J3 > J2 > 201/J1 > J4 Formability J2 (high ductility) > J5 > 201/J1 > J3 > J4 Strength/Hardness J4 (Mn-hardened) > J5 (N-strengthened) > J3 > 201/J1 ≈ J2 Cost 201/J1 (lowest) < J2 < J4 < J3 < J5 (highest) -

Stainless Steel Grades Comparison Table

Grade Characteristics Applications SUS304 Standard 18-8 composition, optimal overall performance, good corrosion resistance Architectural decoration, food equipment, general hardware, structural components 304/304L 304L: Ultra-low carbon, resists intergranular corrosion, superior weldability Welded structures, cryogenic vessels, cookware, food processing equipment 316 Molybdenum-added (2-3%), corrosion resistance >304 (especially pitting/crevice corrosion) Chemical processing pipelines, marine equipment, medical instruments, coastal structures 316L Low-carbon version of 316, resists intergranular corrosion, excellent weldability Premium cookware, pharmaceutical equipment, highly corrosive media containers 302 High-carbon version of 304, significantly increased strength/hardness after cold working Springs, high-strength washers, precision woven mesh, fasteners 310 High Cr-Ni (25Cr-20Ni), excellent high-temperature oxidation resistance (≤1150°C) Furnace internals, combustors, heat exchangers, high-temperature fixtures Performance Ranking

Property Ranking (Best → Poorest) Corrosion Resistance 316L ≈ 316 > 310 > 304L ≈ SUS304 > 302 High-Temperature Performance 310 > 316L > SUS304/304L Strength/Hardness 302 > 310 > 316L ≈ SUS304 -

Stainless Steel Grades Comparison Table

Grade Characteristics Applications 410 Heat-treatable for hardening, moderate corrosion resistance, good strength Bolts, shafts, turbine blades, valve parts 410S Ultra-low carbon, excellent weldability, soft, non-hardenable Furnace components, sheet metal fabrications, annealing containers 420J1 Medium-high carbon, high hardness, wear resistance Cutlery, surgical instrument blades, utility blades 420J2 Higher carbon than J1, maximum hardness (>J1), lower toughness High-wear cutting tools, precision components, razor blades 440 Highest carbon content (~1%), ultimate hardness/wear resistance Premium surgical tools, bearings, precision mold components 409L Lowest cost, thermal fatigue resistance, basic corrosion resistance Automotive exhaust systems (manifolds/front pipes), mufflers 430 Excellent formability, oxidation resistance, cost-effective Appliance surfaces (liners/housings), architectural trim, tableware 439 Ti-stabilized, corrosion resistance ≈304, superior weldability Corrosion-resistant exhausts, water heater tanks, dishwasher components 441 Nb-stabilized, optimal high-temperature strength, fatigue resistance High-performance thin-wall exhausts, fuel cell components Performance Ranking

Property Ranking (Best → Poorest) Hardness 440 > 420J2 > 420J1 > 410 > 430/439/441 > 410S/409L Corrosion Resistance 439/441 ≈ 304 > 440 > 430 > 420 series > 410 > 409L Weldability 439/441/409L/410S > 430 > 410 > 420 series > 440

Key words:

Previous

Next

PRODUCT INQUIRY

Leave Us A Message

Submit your needs and contact information, and our team will respond quickly to provide you with customized solutions. Whether you need information on prices, specifications or custom options, we're here to help. Your satisfaction is our goal.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Us

Address:

No. 20, first floor, Building 8, Lanshi International Metal Trading Market, Chancheng District, Foshan City, Guangdong Province

Service Hotline:

E-mail:

REQUEST QUOTE

Get exclusive discounts, product updates, and expert advice tailored specifically for you!

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSSWE-ASE

https://dc.thefastmake.com/index.html?configure=--enable-dom-interceptor